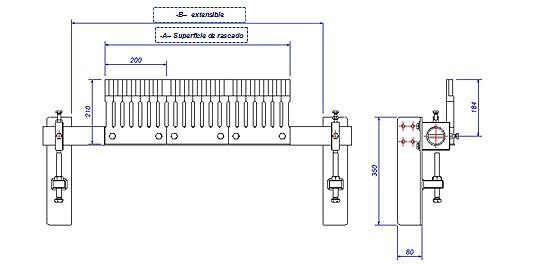

Scraper/Belt Cleaner ‘INBI’ Serie-200 Model ‘N’ & ‘NT’

Serie 124 Mod.’PT’ – Serie 124 Mod.’P-TPU’ – Serie 124 Mod.’P-PU’ – Serie 124 Mod.’ST ST/MU’ – Serie 124 Mod. ‘S-PU’ – Serie 150 Mod.’P-PU’ – Serie 150 Mod.’P-PU STRONG’ – Serie 150 Mod.’DST’ – Serie 200 Mod.’N y NT’ – Serie 200 Mod.’E’

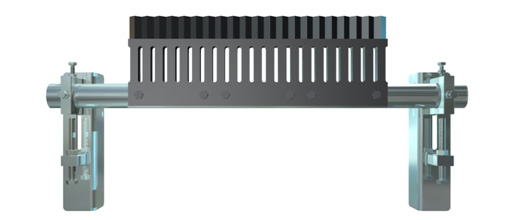

The scrapers ‘INBI’ S-200 models ‘N’ & ‘NT’ are scrapers specially designed for the cleaning of the ribbed belts.

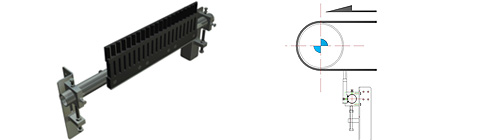

The positioning of these scrapers can be in the driving drum or in the return of the belt.

SERIE 200 Models ‘N’ and ‘NT’ – CHARACTERISTICS

The scraper blades are specially designed for the cleaning of the ribbed belts and they are manufactured in polyurethane with a high degree of resistance to the abrasion. Each blade, with 200mm width, has seven fingers very flexible that adapt completely to the ribs of the conveyor belt, making their cleaning possible without any type of damages in the same ones.

The model ‘NT’, especially designed for materials highly abrasive, has an index in Tungsten in each finger.

The scraper blades are fixed to the axis by means of two screws, which does that his substitution is fast and simple.

The support of the scraper has a sliding system to facilitate the positioning.

The pressure system, adjustable by screw, is assemble on the lateral supports.

ADVANTAGES

- Reduce the production cost.

- Efficient cleaning due to the adaptability of the blades.

- Long operationg times due to the high resistance to abrasión of the blades.

- Easy installation.

- Minimum maintenance.

- Require small installation space.

- Easy adjustment.

- Easy and quick replacement of spare parts.

APPLICATIONS

- For belt width from 400 to 2000mm.

- Scraper for ribbed-chevron belts.

- Belt speed <3 m/s.

- Temperature range: –30º to +80ºC

- It can be used in belts with staples unions.

Contact our technical department for any questions or queries you may have.

Tlf: 944 572 125 / E-mail: cintrolsl@cintrolsl.com